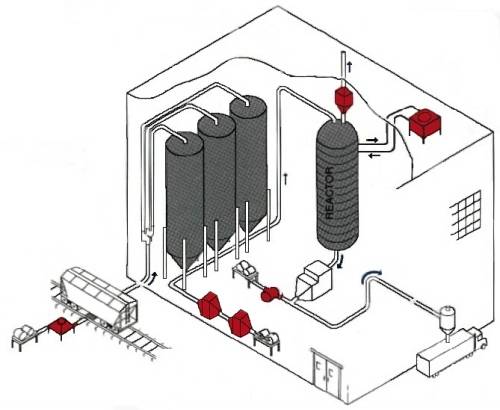

This application diagram illustrates demonstrates how Xchanger heat exchangers are used in a variety of applications.

| The red items are Xchanger heat exchangers |

|

|

High volume, low pressure flows, such as those produced by rotary lobe (Roots type) blowers and multi-stage centrifugal require unrestrictive, free-flowing heat exchangers. Low pressure air heat transfer is an Xchanger specialty. In most applications, the pressure drop through our exchangers is under 5 inches of water column (or 1/4 PSI).

Xchanger heat exchangers can be designed to cool, heat, or dehumidify air streams. Service fluids including steam, refrigerant, oils, water, liquid nitrogen, and ambient air are used to accomplish a wide variety of heat transfer goals.

All Xchanger heat exchangers are designed using extended (fin) surface. Finned heat exchangers are very advantageous with air or other gases – they’re nearly as effective as bare tubes and a fraction of the cost. This type of surface is very effective in liquid-air or air-air heat transfer applications, but it is not suitable for liquid-liquid service.

Common uses of Xchanger heat exchangers include:

• Cooling pneumatic conveying air to prevent the conveyed product from temperature related degradation such as melting.

• Heating pneumatic conveying air to prevent condensation or line plugging.

• Dehumidifying conveying air to prevent moisture gain in hygroscopic products.

• Precooling / Intercooling vacuum pumps to protect the pumps from high temperatures.

• Cooling air/vapor streams headed for activated carbon beds used in soil remediation.

• Heating air to regenerate desiccant in air dryers.

• Cooling compressed air or liquids with ambient air.

• Process air heating, cooling, or dehumidifying.

• Condensing solvent vapors at storage tank and reactor vents.