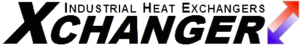

AA Series heat exchangers cool low pressure gas streams with ambient air. These compact air cooled units are ideal for locations with limited access to cooling water and have significantly lower operating costs compared to heat exchangers that require a cooling water system. They feature a TEFC 230/460 VAC, 3 phase motor, a heavy-duty cooling fan and an OSHA approved fan guard. Alternate motors are available upon request. The exhaust hood and venturi frame are galvanized steel. Use our interactive online form to get a fast and accurate quote!

AA Series heat exchangers cool low pressure gas streams with ambient air. These compact air cooled units are ideal for locations with limited access to cooling water and have significantly lower operating costs compared to heat exchangers that require a cooling water system. They feature a TEFC 230/460 VAC, 3 phase motor, a heavy-duty cooling fan and an OSHA approved fan guard. Alternate motors are available upon request. The exhaust hood and venturi frame are galvanized steel. Use our interactive online form to get a fast and accurate quote!

Common Applications

Aftercooling Roots type (rotary-lobe) and multistage centrifugal blowers used in pneumatic conveying, biogas, coal-seam methane, and wastewater aeration systems.

Core Construction

The aluminum plate-fin heat exchanger core is furnace brazed with alternating finned flow channels. Process gas flows in horizontal channels, and ambient cooling air flows upward, through vertical channels. The process stream enters and exits through rectangular aluminum headers, which are welded to the core.

Operational Considerations

The process stream must be filtered to ensure particulate will not obstruct the passages. If necessary, the service side can usually be cleaned with a soapy water wash. The process channels should not be considered cleanable due to their long enclosed flow length.

Installation Considerations

Pulsating flow, such as that produced by rotary lobe blowers should be dampened by a chambered silencer. AA Series heat exchangers dissipate heat from the process stream to the ambient environment. They are designed for outdoor installation. If installed indoors, the area should be very well ventilated.

Performance

Xchanger engineers use a computer model to analyze heat exchanger performance based on the best available engineering practice. A database with fan performance data allows us to select the best fan for the application.

Models

AA-250, AA-400, AA-500, AA-750, AA-1000, AA-1750, AA-2000, AA-2750 & AA-3500.

Special Configurations

Can be found on our Custom Designs page.

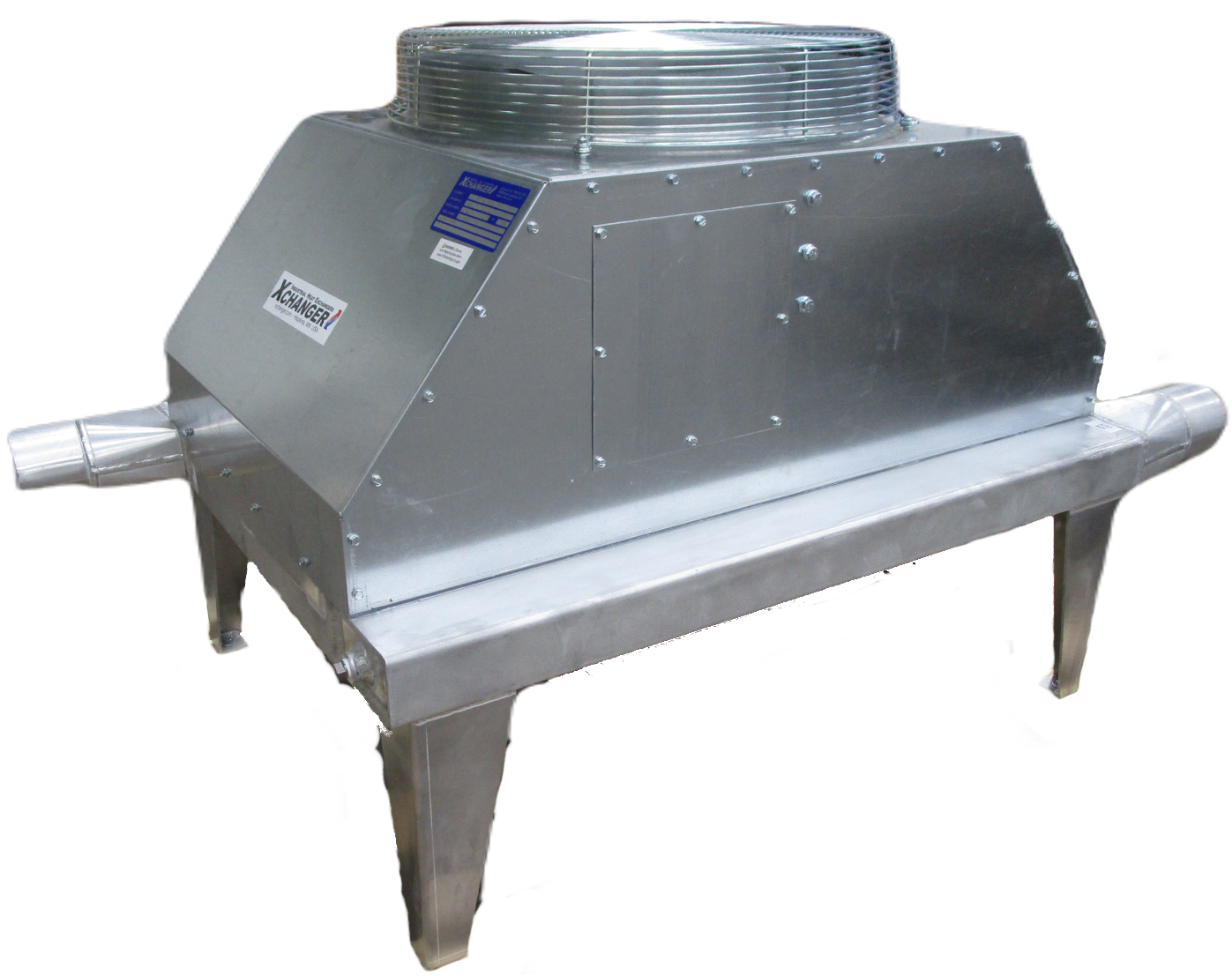

Air cooled heat exchanger (blower aftercooler) isometric drawing and typical configurations:

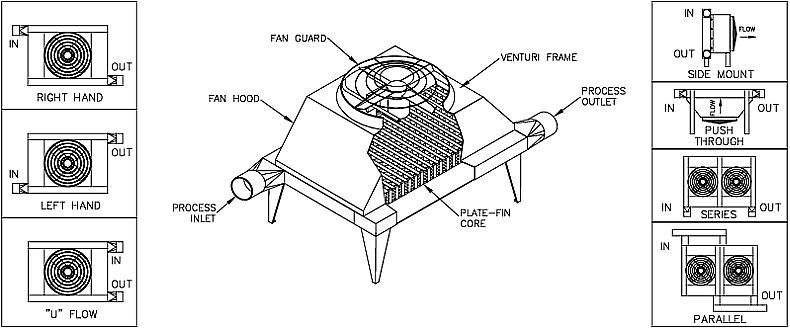

Sample data sheet: